It’s no secret that high wattage DE-HPS lamps produce lots of plant-usable light, with photon efficiency above the “glass ceiling” of 2.0 µmol / J. Since their introduction over a decade ago they have been causing quite a stir in the indoor gardening world as growers know: light and productivity are intrinsically linked! However, many indoor growers—especially medium to large scale commercial cultivators—have adopted practices that negate the potential efficiency gains of DE-HPS technology.

Now ALL indoor growers (even those with regular height ceilings) can benefit from DE-HPS grow light technology, without having to compromise with high hanging distances. Learn how Adjust-A-Wings brings superior efficiency to your grow room.

Lights Hoisted Up High

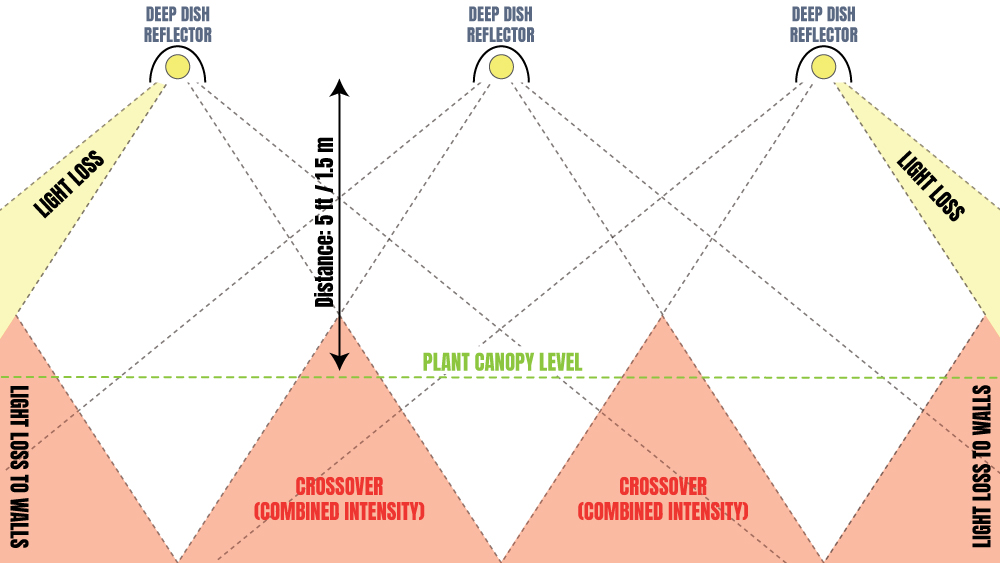

You’ve no doubt seen dozens of similar photos on your Instagram or Facebook feed: row after row of 1000W DE-HPS lights in small, deep-dish “greenhouse style” reflectors raised up 5, 6 or even 8 feet above the plants. These images are so ubiquitous at the moment that new growers could be forgiven for thinking that this is the only way it’s done.

The most commonly cited reason for the “hoist ‘em up high” approach is overall light uniformity—the desired PPFD (light intensity) levels (typically 700 – 900 µmol) can certainly be achieved with 1000W DE-HPS lamps positioned in a 4 / 6 matrix. (Fixtures positioned so there are 4 feet between each column and 6 feet in between each row—with the lamps positioned so they run in line with the rows / perpendicular to the columns).

High Lamp Placement Reduces Intensity

High Placement of Deep Dish Style Reflectors

in a Commercial Greenhouse

The sacrifice demanded by this “brute force” approach is overall efficiency. The high placement of the lamps means that by the time the light reaches the plant it has decreased exponentially in intensity. These small reflectors cast a very wide spread of light which relies on cross reflection from neighboring fixtures in order to achieve the desired PPFD. This inexorably leads to huge light losses to walls, floors and walkways. Also, by the time the light reaches the plants it has decreased exponentially in intensity meaning canopy penetration is significantly reduced. This concentrates growth and development at the top of the plant with little to no productivity just a few inches below.

Why So High?

Small, deep-dish “greenhouse style” reflectors trap heat. They were designed to cast a minimal shadow in greenhouses so they could be effectively used to supplement sunlight. In an indoor growing situation where grow lights form the sole light source for plants a different solution is needed—one where heat is dissipated and not trapped, and light is safely directed to plants at maximum intensity.

The common high placement of 1000W DE-HPS lamps (and lack of height adjustment throughout the lifecycle) is a “brute force” approach to indoor gardening. The high placement is necessary because of the sheer physical heat trapped inside the small reflectors and the need to keep this away from plants. It’s not just the convection heat but also the radiant heat. Small deep-dish reflectors re-emit infrared as mid to far infrared. Certain wavelengths in this range are known to be highly effective at heating up di-polar molecules such as water. When plants (which are full of water) overheat they become stressed and perform sub-optimally. In a nutshell, they focus on surviving rather than thriving.

Significant Efficiency Losses

The high placement of greenhouse style reflectors may help to mitigate the inherent convection and radiant heat issues but the light losses (and additional fixtures required) generate more overall heat and necessitate even more energy use in the form of cooling. Moreover, the higher running temperatures inside these fixtures can prematurely age lamps meaning that any supposed “labor savings” of not adjusting the height of the fixtures throughout the lifecycle are lost as re-lamping typically needs to occur every 12 months (compared with every 18 months with more efficient and forgiving fixtures.)

There is a Better Way!

Yes, DE-HPS lamps produce lots of heat. Growers are aware of the notorious “hot spots” that occur directly beneath the lamp. Less known is the fact that ingenious technologies have been developed to directly counteract these hotspots.

The new Adjust-A-Wings Hellion 600-750W DE-HPS Illumination Kits come with an amazing device known as a “Super Spreader” which is positioned directly beneath the lamp. This spreads not only the light but the radiant heat, affording a much closer placement between the fixture and the plant canopy—as close as 45 cm (18”) for 750W DE-HPS!

This is revolutionary on a number of levels. Plants can enjoy maximum intensity from DE-HPS lamps (fully realizing their efficiency benefits) with deep penetration into the plant canopy (strong, intense and angular light) with good uniformity and minimal light losses to walls and pathways.

The double-parabolic reflector so synonymous with Adjust-A-Wings creates a beautifully uniform and even light pattern and dissipates heat. Adjust-A-Wings reflectors run much cooler (< 90⁰C) than deep dish-shaped greenhouse style reflectors (> 200⁰C). So unlike greenhouse style reflectors which degrade by 3-5% in reflectance each year, they carry on working perfectly for many years (3 to 5 years at least) without significant degradation. Also, because they run much cooler, lamps last longer with higher lumen maintenance (Adjust-A-Wings recommend lamp replacements every 18 months whereas other manufacturers recommend 12 months) and there is massively reduced infrared re-emittance which can potentially cause issues for heat sensitive crops.

Increased Lighting Efficiency Reduces HVAC Overheads

If growers can use fewer watts (typically 35W per square foot rather than 50W per square foot) then they generate less heat load for their HVAC systems. Often cooling costs can be reduced by 30 percent or more. Meanwhile, production is not limited exclusively to canopy-level flowering and fruiting sites but deep into second and third tier sites too.